What can’t be bought, we develop ourselves

Particle physics is complex and expensive. Large research infrastructures, such as the Large Hadron Collider (LHC) at CERN with its four detectors, cost billions. If researchers are asked what it’s all for, they have a few good answers ready. Above all, they say, it’s about gaining new insights, extending the boundaries of knowledge. In addition, in the large laboratories, thousands of skilled workers would be trained to use the latest technologies and work in interdisciplinary teams – a blessing for high-tech industry, and not only in Switzerland. Another argument: we are developing new technologies that could also be of interest for industrial applications.

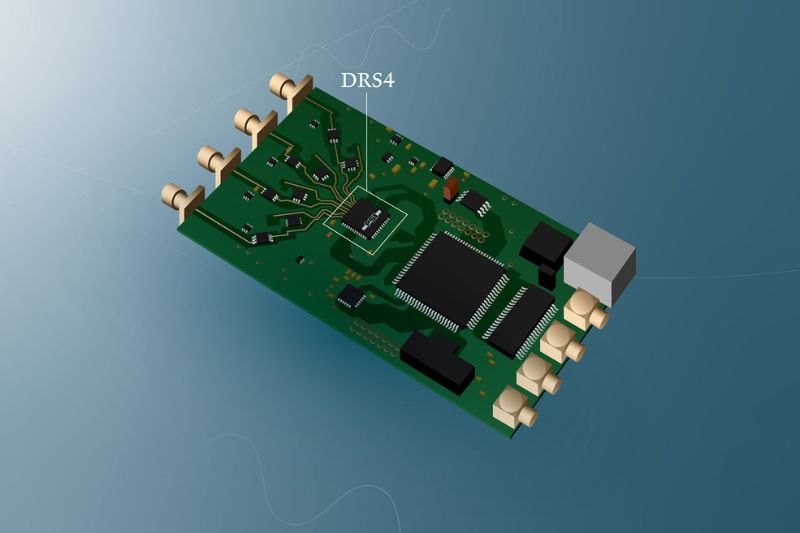

The latter is Stefan Ritt’s hobbyhorse. The PSI research group leader is both a physicist and an enthusiastic tinkerer. If an experiment at PSI requires a particular electronic circuit that cannot be purchased anywhere, he doesn’t hesitate to get out the soldering iron and build it himself. In this way he achieved a milestone ten years ago: DRS4. This “domino ring sampler” is a microchip that, simply put, integrates an ultrafast oscilloscope on a surface the size of a fingernail. The temporal resolution is less than ten trillionths of a second. This enables researchers to detect particles produced by muon decay processes. The high temporal resolution and enormous speed of the chip are necessary because, in these experiments at PSI, 30 million such decays take place every second, and their signals overlap. That’s what makes the analysis so tricky.

One of the most loyal “customers” is Aldo Antognini with his experiments to determine the proton radius. But he’s not the only one: numerous research laboratories around the world use the DRS4. For example, medical researchers in Tübingen, Germany, use it to localise brain tumours with pinpoint accuracy. Ten thousand units of the DRS4 have already been sold. Due to such high demand, the chips are now manufactured in Taiwan and sold by RADEC GmbH, a PSI spinoff based in Koblenz, Switzerland. The company of the former PSI physicist Radoslaw Marcinkowski provides services for space missions, excellent proof that PSI know-how is valued and put to use far beyond its gates.

In use worldwide

But one thing is important to Stefan Ritt: “We don’t pursue commercial interests. We sell the chips and the associated electronics boards at cost.” The research mission of PSI always comes first. This also applies to the electronics and software that Ritt’s team is currently developing for new, very fast particle detectors. In the future, Ritt would also like to improve the DRS4 chip so that the data can be read out even faster.

Even if PSI develops hardware and software mainly for its own research purposes, that doesn’t mean this research has to take place on its Villigen campus. PSI researchers are also involved in collaborations at other research centres, especially CERN in Geneva. With the large proton accelerator LHC, this provides the infrastructure, while on the other hand the detectors CMS, ATLAS, LHCb, and ALICE are operated by international consortia. At CMS alone, around 200 research institutes from around the world are involved, with more than 5,800 researchers, administrative staff, and technicians. Each partner contributes a part to the detector and its operation, and in return may use the data.

One immensely important component of CMS, which is as big as a multifamily residential building and weighs 12,500 tonnes, is the silicon pixel detector. It sits deep inside CMS and is comparatively small, but it fulfils an important function. By analysing the charged particles created during proton collisions, it measures the location where each collision took place with micrometre precision. This location is the basis for the measurements of the other detectors surrounding the silicon pixel detector – which was developed and built at PSI – like layers of an onion.

In principle, the detector is a digital camera with 124 million pixels, 150 by 100 micrometres, measuring not light but rather charged particles – 40 million times per second. The first detector, which went into operation with the LHC in 2008, consisted of three cylindrical layers; the second evolutionary stage, with four layers and faster electronics, is now in operation.

For the next stage in the expansion of the LHC, planned to start in 2029, even this detector is much too slow. The LHC’s luminosity – its brightness, you could say – will increase fivefold, and CMS will have to process a correspondingly larger number of particle collisions. For this third generation of the pixel detector, Lea Caminada, head of the ten-person high-energy physics group at PSI and professor at the University of Zurich, came up with something new: the Tracker Extended PiXel System. TEPX is designed to cover a still larger solid angle and should also register particles that fly forwards or backwards in approximately the direction of these beams. That is important because certain exotic particles – including the famous Higgs particle – exhibit signatures that can only be measured at those locations, and are currently not covered. Because the surface area of the detector will be much larger and twice as many modules will be installed, the team is developing a robot to automate assembly.

The Swiss economy benefits

The in-house development of pixel detectors also benefits other research fields, such as muon spin spectroscopy. This can be used to determine the magnetic properties of materials, including some that might be used to build future quantum computers. In a magnetic field, the material is bombarded with muons, which decay into positrons within microseconds. From the temporal distribution of the positrons, the researchers can deduce the magnetisation of the material. Up to now, this has only been possible if the muons arrive one after the other. PSI’s fast detector would allow the simultaneous measurement of many muons, which would multiply the measurement rate and deliver a three-dimensional image of the magnetisation inside the material.

Such an apparatus could also be of interest for industrial applications. Christian Brönnimann, former doctoral researcher at PSI and founder of the PSI spinoff company DECTRIS AG in Baden-Dättwil, co-developed the first silicon pixel detector for CMS and made it into a commercially successful product. The DECTRIS detectors are at the forefront of X-ray analysis. One specialty of the company is hybrid detectors that can simultaneously count electrons as well. “Through the fundamental research at PSI, positions for 100 highly qualified workers have been created,” Brönnimann says. DECTRIS and PSI are still working together today. Lea Caminada: “We support each other with knowhow in the development and construction of new detectors. Our research profits from this, and so does the Swiss economy.”