ETH students develop drones, robots and vehicles

Ten teams have spent a year developing prototypes that demonstrate the current state of the art in the areas of additive manufacturing, robotics, and drive and transport technologies. The Focus projects are an integral part of a Bachelor’s degree in mechanical and process engineering. The students complete the entire process independently – from the project idea and design studies through to the search for sponsors and production. These are the projects they have realised this year:

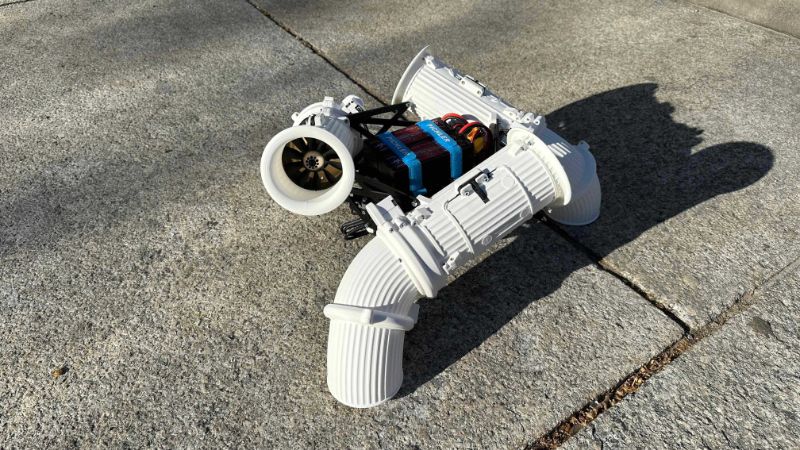

AVERO – the safe inspection drone

Drone propellers pose a risk: people can injure themselves on their rotating blades, and objects or the drone itself can be damaged in the event of collisions. The eleven-strong team of the AVERO Focus project consequently undertook to move the propellers to the drone’s interior, placing the propellers in tubes while using pivoted nozzles to control the air current generated.

The innovative propulsion offers further advantages: the drone can rotate in any position around two axles more than conventional models and fly closely alongside objects. Possible fields of deployment are inspections of infrastructures that are difficult to access and in busy environments such as building sites.

RAPTURE – 3D printing for multi-material rocket parts

Additive manufacturing involves creating components layer by layer. One of these 3D printing processes is the repeated application and selective fusing of metal powder with a laser. This technique enables the construction of components with particularly fine and complex geometries. In the RAPTURE Focus project, students developed a new machine architecture that enables them to manufacture parts from two different metals. To this end, they are working on a particularly fast and material-saving technique that can be deployed in aerospace and many other sectors. The students aim to use this technique to make special components such as nozzles and other engine components with customised material properties. The technology promises to enhance the cost efficiency and performance of rocket systems.

SARA – Soft Actuated Robotic Arm

Despite major progress, upper-limb prostheses are still frequently perceived as being too heavy. The SARA Focus project therefore aims to construct a lightweight and flexible robotic arm that can be further developed into a prosthesis. The vision of the students in the project team is for users of prostheses to be barely aware of their disadvantages in the future.

With the development of the robotic arm, they plan to pave the way for a new generation of lightweight, agile and silent prostheses. Instead of conventional actuators, the students are making use of a new robotics technology that copies how human muscles work. The actuators – in other words, the elements that generate movement – consist of liquids in thin plastic films that convert electrical into mechanical energy. By integrating artificial muscles into the arm prosthesis, the students aim to make the latter more agile and at the same time more lightweight.

Other Focus projects in 2023/24

- aCentauri is constructing an aerodynamic racing car powered exclusively by solar cells and capable of reaching motorway speeds. The team will be entering the World Solar Challenge, which covers 3,000 km in the Australian outback, for the second time in the autumn of 2025.

- aidara is developing a robot assistant known as a “cobot” that is capable of understanding tasks and identifying objects independently thanks to AI-based speech and image recognition algorithms. The robotic arm serves as a “third hand” and hands over objects on request.

- Cellsius Project H2 is developing a hydrogen powertrain for a light aircraft. The two-seater aircraft is to be emission-free, quiet and economical and offer an environmentally friendly alternative for training and leisure flights.

- Formula Student Electric is pursuing the goal of further boosting the performance of electric racing cars. The car is being assembled following a four-month development phase. The team is entering their prototype in the annual “Formula Student” contest.

- LEVA is constructing a robot that is capable of lifting and carrying boxes on its own and moves like a four-legged animal. It can be deployed in confined spaces and on uneven terrain and is intended to make work on building sites, in agriculture and intralogistics safer and more efficient.

- NOCTUA is developing a quiet long-range drone for the surveillance of wild animals in African wildlife reserves. Around 90 elephants and two rhinos fall victim to poachers there every day. The drone is designed to fly autonomously over large areas for up to 12 hours without disturbing the animals.

- Swissloop is further developing its carbon-neutral high-speed transport system Hyperloop. It is taking part in the European Hyperloop Week, an international competitive event, with its new levitating pod in which goods and passengers are to be transported in future at speeds of up to 1,000 km/h.