New Eawag spin-off advises wastewater treatment plant

What made you decide to set up a spin-off?

Wenzel Gruber: In our research on microbiology and greenhouse gas emissions from wastewater treatment plants, we have seen the practical application possibilities and also the need for these on the part of practitioners.

Robert Niederdorfer: For this reason, we did not just want to pass on our research findings via publications, as it was clear to us that these insights had to go to the market, because there was a real benefit for wastewater treatment plants.

Wenzel Gruber: But we didn’t find any partners who had the relevant know-how and at the same time were willing to bear the risks of such a start-up. So at some point, we decided that we would try it ourselves.

What services does Upwater offer?

Wenzel Gruber: We offer, for example, exhaust air measurements in order to record emissions of nitrous oxide, a significant greenhouse gas, from the wastewater treatment plants and to be able to propose measures for reduction. In addition, we can also determine the oxygen transfer with this method, i.e. how well the oxygen injected in the biological treatment stage reaches the reactor. Up to now, this has been a black box. Aeration is responsible for most of the energy consumption of wastewater treatment plants – thanks to our measurements, this can be optimised.

You also offer microbial monitoring as a further service for wastewater treatment plants. Why?

Robert Niederdorfer: Bacteria are responsible for all purification processes in wastewater treatment plants to break down nutrients and pollutants. However, the composition of this microbial community in the wastewater treatment plants can change, for example, due to the change of seasons or how the installation is operated. With our research, we were able to show that this can lead to instabilities in the purification process.

What consequences does this have for wastewater treatment plants?

Robert Niederdorfer: For example, nitrous oxide emissions may increase or it may no longer be possible for the wastewater treatment plants to provide the required cleaning performance. The advantage, however, is that you can observe changes within the microbiome before such problems occur. So you have some lead time. If we examine the microbiome weekly in samples from the wastewater treatment plants using DNA sequencing, we can first determine the basic state and then, based on that, predict when problems will occur. In this way, we offer an early warning system.

Wenzel Gruber: It is important to us that we speak the language of the operators of the wastewater treatment plants and can explain to them in an understandable way what the collected data means.

Robert Niederdorfer: For this purpose, we divide the microorganisms into the functional groups that are relevant for wastewater treatment plants and show with analyses and graphics what has changed compared to the previous week and what could happen as a result.

Do you already have orders for all the services you offer?

Wenzel Gruber: Yes, we were able to start preparing offers for clients from day 1 of our spin-off. Eawag’s network is worth its weight in gold. In particular, the process engineering department has a very strong practical orientation and many contacts with practitioners. We benefit a lot from this.

Robert Niederdorfer: In addition, we can also draw on our internal Eawag network and its scientific expertise. That will also be very helpful to us.

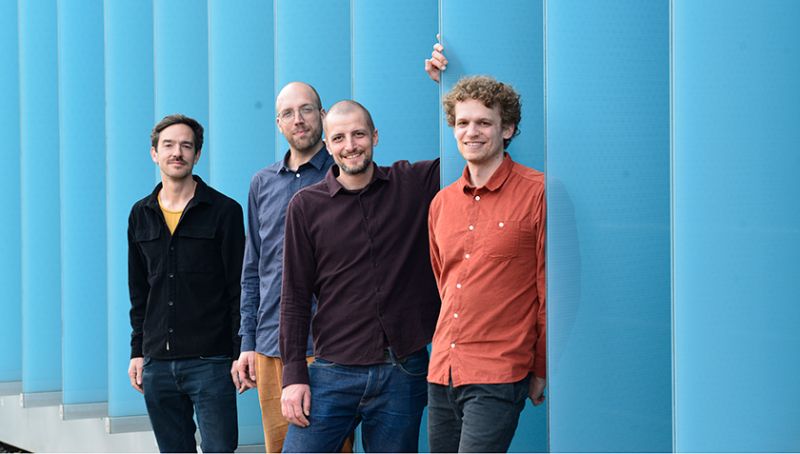

It took four of you to found your spin-off. Why did you bring two more partners on board?

Wenzel Gruber: We had so many orders for exhaust air measurements that I couldn’t manage them all on my own. That’s why I’m going to do this together with Manuel Layer, who also has experience with exhaust air measurement technology. Like me, he is a process engineer, was also a postdoc at Eawag and has spent the last two years working in an engineering office.

And then Jonas Ruggle is also part of Upwater. He is a computer scientist and environmental engineer and has already worked in a start-up for five years. At Upwater, he will develop software for the evaluation of our measurement data and take care of the accounting.

What are your medium and long-term objectives?

Wenzel Gruber: My objective is clearly to reduce greenhouse gas emissions from wastewater treatment plants. And for me personally – to have an exciting job.

Robert Niederdorfer: That is exactly the same for me. I find it extremely fascinating to understand the microbiome better and to use this to optimise processes in wastewater treatment plants.

Wenzel Gruber: Switzerland has 280 wastewater treatment plants that are of interest to us. Therefore, it would certainly be possible to build up our service in Switzerland in a sustainable way.

Robert Niederdorfer: And then, of course, there is Germany and Austria where you can expand.